In the realm of workplace safety, preparation is paramount. One crucial tool that aids in emergency preparedness is the emergency equipment diagram. This comprehensive guide delves into the essence of emergency equipment diagrams, their importance, and how to optimize them effectively.

Understanding Emergency Equipment Diagrams

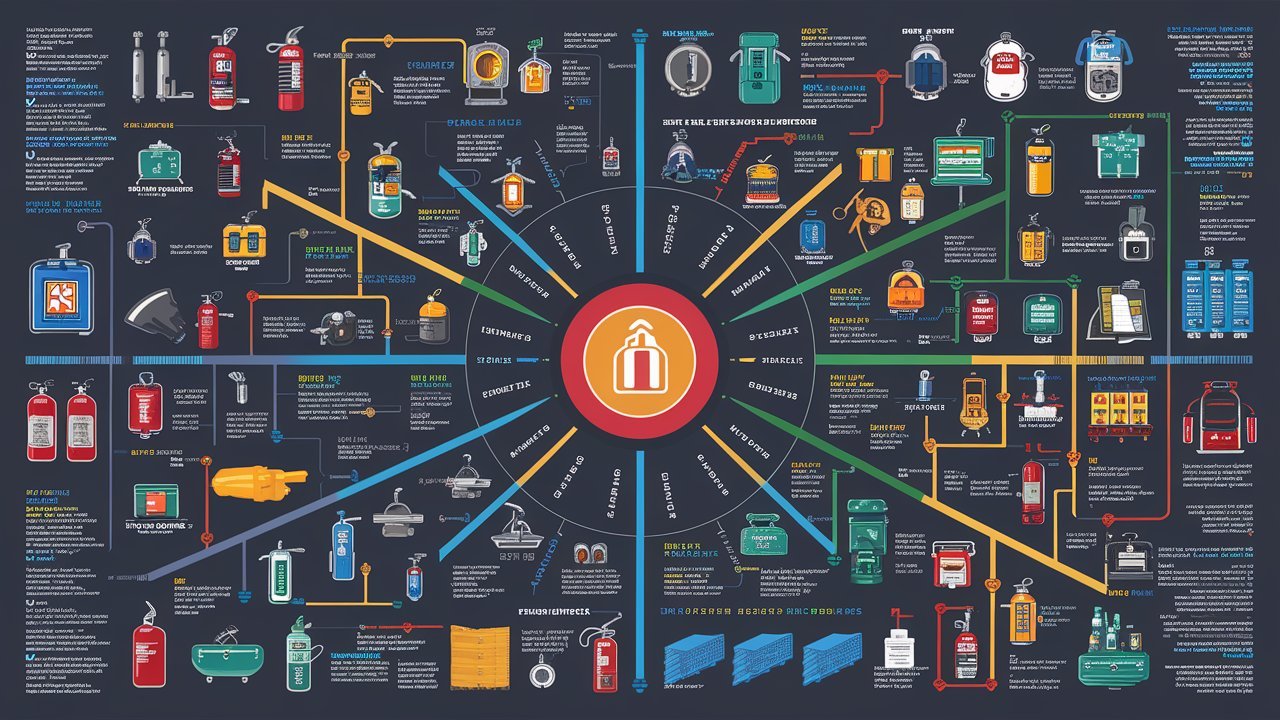

An emergency equipment diagram is a visual representation outlining the location and functionality of various safety equipment within a facility. These diagrams serve as vital resources during critical situations, providing clear guidance on accessing essential tools like fire extinguishers, first aid kits, and emergency exits.

Components of an Emergency Equipment Diagram

Emergency equipment diagrams typically include detailed depictions of:

- Emergency exits

- Fire extinguisher locations

- First aid kit placements

- Emergency shower and eyewash stations

- AED (Automated External Defibrillator) locations

Benefits of Emergency Equipment Diagrams

Emergency equipment diagrams offer numerous benefits, including:

- Enhanced Safety Preparedness: By providing clear visual cues, these diagrams empower individuals to respond swiftly and effectively during emergencies.

- Regulatory Compliance: Many jurisdictions mandate the presence of emergency equipment diagrams as part of workplace safety regulations.

- Risk Mitigation: Accessible diagrams reduce the risk of confusion or delay during critical situations, potentially averting accidents or injuries.

How to Create an Emergency Equipment Diagram

Creating an effective emergency equipment diagram involves the following steps:

- Assessment: Conduct a comprehensive assessment of your facility to identify key safety equipment and their optimal placement.

- Design: Utilize specialized software or design tools to create a clear and concise diagram, ensuring accurate representation of each safety component.

- Labeling: Clearly label each safety feature on the diagram, using standardized symbols or icons for easy comprehension.

- Accessibility: Ensure the emergency equipment diagram is prominently displayed in high-traffic areas and remains easily accessible to all personnel.

Examples of Emergency Equipment Diagrams

Here are some common examples of emergency equipment diagrams:

- Office Buildings: Diagrams highlighting fire extinguisher locations, emergency exits, and evacuation routes.

- Manufacturing Facilities: Comprehensive diagrams featuring additional safety equipment such as eyewash stations and spill containment measures.

- Laboratories: Specialized diagrams detailing the locations of chemical spill kits, emergency showers, and safety showers.

Importance of Regularly Updating Emergency Equipment Diagrams

Regular updates to emergency equipment diagrams are essential to ensure accuracy and relevance. Changes in facility layout, safety regulations, or the addition of new equipment necessitate prompt updates to maintain effectiveness.

Common Mistakes to Avoid When Creating Emergency Equipment Diagrams

When crafting emergency equipment diagrams, it’s crucial to avoid common pitfalls such as:

- Inaccurate Information: Ensure all details depicted on the diagram are current and precise to avoid confusion during emergencies.

- Poor Visibility: Opt for clear, high-resolution graphics and ensure adequate lighting in areas where the diagram is displayed.

- Lack of Accessibility: Place emergency equipment diagrams in prominent locations where they are easily visible to all occupants.

Emergency Equipment Diagram Best Practices

To optimize the efficacy of emergency equipment diagrams, consider the following best practices:

- Regular Reviews: Conduct periodic reviews of emergency equipment diagrams to identify any necessary updates or revisions.

- Employee Training: Provide comprehensive training to all personnel regarding the use and interpretation of emergency equipment diagrams.

- Accessibility: Ensure that emergency equipment diagrams are available in multiple languages and formats to accommodate diverse workplace populations.

FAQs

- What should be included in an emergency equipment diagram?

- How often should emergency equipment diagrams be updated?

- Can emergency equipment diagrams vary by industry?

- Are there any regulations regarding emergency equipment diagrams?

- What should I do if I notice errors in an emergency equipment diagram?

- How can I ensure my emergency equipment diagram is accessible to all employees?